Esfarayen Industrial Complex at a Glance As the largest producer of wrought alloy steel sections and parts in Iran, Esfarayen industrial complex is known as the center of alloy steel industry in Iran and the Middle East. This company formally started its

activity as a full manufacturing process from 2005 through full utilization of various production units, including melting and expendable casting unit, radial forge and heavy press unit, heating and heat treatment unit, and heavy and light machining unit.

This complex will offer its capabilities more than ever in the near future through establishing continuous casting lines, Electro Slag Remelting (ESR) production line, machining and heat treatment of super heavy parts. Steelmaking unit: Special alloy steel

production requires advanced equipment and processes that could produce homogeneous steel, clear in terms of the presence of non-metallic inclusions, with lowest value of the unwanted elements such as sulfur, phosphorus, and also the least amount of gas. Therefore,

melting and casting workshop of the complex has been designed and implemented to prepare high-quality alloy steel ingots including melting, secondary metallurgy and ingot casting processes . •The main equipment of this unit includes: 1.Electric Arc Furnace

(EAF) with EBT system and a capacity of 50 tons and capable of blowing oxygen and carbon to produce low phosphorus steel 2.Ladle furnace ( LF ) with a capacity of 50 tons and Argon bottom-blowing system with high purity for flotation and removal of melt impurities

and desulfurization. 3.VD System ( Vacuum degasing ) with a capacity of 50 tons for melt degasing under vacuum of 2mbar and production of steels with: H <1.5ppm N <60PPM O <50PPM S <8PPM 4.VOD System ( Vacuum Oxygen Decaburization ): for production of alloy

steels (Stainless Steel) with c<0.03% 5.VSD ( Vacuum Stream Degasing ): vacuum stream casting to produce ultra-heavy ingots of 50t, 80t and 120t 6.Ingot casting capable of producing alloy ingots of 2.2t to 120t 7.Alloy steel casting line up to 100 tons Radial

Forge Unit Forging production line has been designed to produce specific alloy steel products with high quality and mechanical properties. An important advantage of radial forging process is the ability to work at low tolerances and consequently, greater efficiency,

which is very considerable in case of special steels and superalloys. This line is equipped with five radial forge machines from GFM Company (Austria) which will be able to produce different types of alloy steels with various sections, including round, square,

rounded corner square (RCS ), hexagon, octagon, conical, thick wall and stepped pipes with required metallurgical controls. The main equipment of the workshop includes: •Radial forging machine SXP-65, maximum turning diameter of 650mm •Radial forging machine

SXP-25, maximum turning diameter of 250mm •Radial forging machine SXP-13, maximum turning diameter of 130mm •Radial forging machine SXP-10, maximum turning diameter of 100mm •Radial forging machine SHP-06, maximum turning diameter of 60mm •5 preheating furnaces

•5 heat treatment furnaces, for annealing, normalizing , quenching and tempering heat treatments •Workshop heavy and light transportation equipment Due to the unique specifications of this equipment, it is able to produce a variety of grades of cold work tool,

hot work tool, plastic mold and stainless steel (austenitic, martensitic, ferritic and precipitation hardening). Production capacity of the plant is 48 thousand tons per year. Open Die Press production line Forging operations of large steel sections require

special and unique technology. In sections with diameter of above 500 mm, forging and transforming ingots require a great power, due to their high strength and weigh. Thus, to provide self-sufficiency and exports in production of large wrought alloy parts

and sections in the country, Heavy-Duty Press Workshop of this complex have been implemented through installation of a hydraulic press machine with a power capacity of 6,300 tons (SKODA Company from Czech Republic) and other equipment. •This equipment can

produce a variety of round, square, slab, and stepped sections, and heavy-duty rollers, power plant shafts, ring, disk and thick-walled pipes in various alloy steels. Also, this machine is capable of forging parts up to weight of 120 tons and according to

the mentioned characteristics, the capability of the device is exclusive in the Middle East and is able to supply a part of regional requirements. The main equipment of the workshop includes: •Two-column hydraulic press with a power of 6300 tons •Manipulator

of 80 tons •5 preheating furnaces up to 5 tons •5 heat treatment furnaces up to 120 tons •Workshop heavy and light transportation equipment up to weigh of 150 tons •Flame cutting up to 1500 mm diameter Production capacity of this workshop is 48 thousand tons

per year. Heat treatment line This line includes several different types of heat treatment furnaces up to a capacity of 120 in which various cycles of annealing, normalizing, quenching and tempering heat treatments will be applied to the parts (through immersion

method) to obtain the mechanical properties and microstructure commensurate with world standards and customer demands. The existing reservoirs containing oil and water in this line along with high speed cranes and lifting tools, are able to apply various quench

heat treatments up to weighs about 100 tons to the parts. The furnace with proper temperature tolerance and equipped with accurate thermocouples ensures the achievement of appropriate structure and properties of products after heat treatment. Also, the development

plan of using polymer quenching environment for heat treatment of various high alloy steels has been predicted in supplementary plan of this complex which will be added to the abilities of the complex in the near future. Machining unit: Having Turning, CNC

and Milling machines in different sizes along with Deep Hole Drilling equipments, this unit has the ability to offer products as rough turning and accurate turning. This complex designs and controls the production of high quality products via following technical

support units. Engineering and Research Unit This unit is responsible for designing, reviewing, confirming and validation of the complex manufacturing processes, management of technical knowledge and research and development (R & D) of the following products:

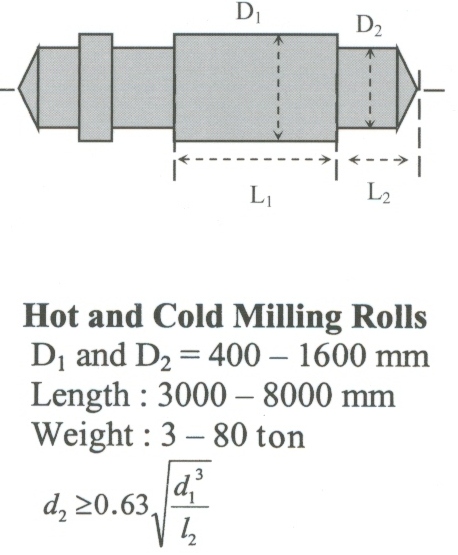

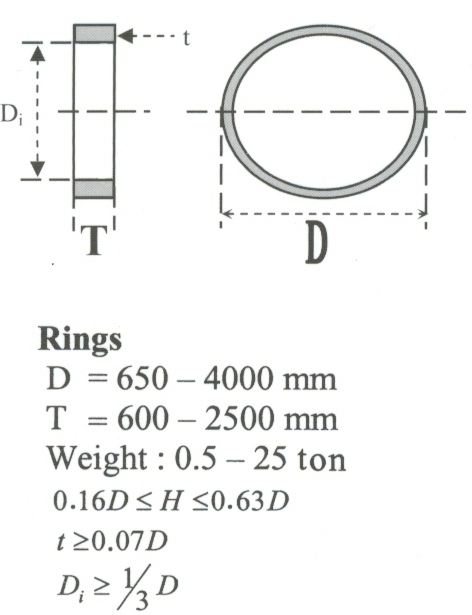

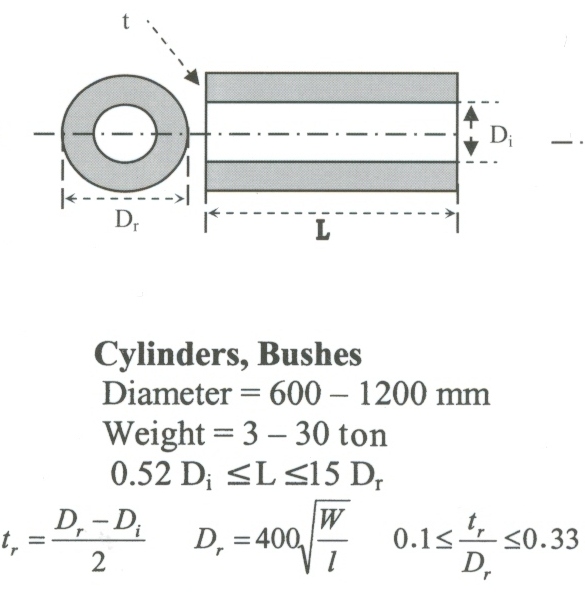

1 - Steel Parts with complexity in terms of the product shape, chemical compound, or both; these parts include: Various types of backup rolls and work rolls in roll industries, drilling bits, conical shafts of mining Stone Breaker Machines, a variety of thick-walled

pipes with application in the fields of oil, gas and petrochemicals, adapter and various high-dimensional rings, for - high-dimensional slabs, various high-diameter discs and ... 2 – Parts with high complexity of chemical compounds and the expected metallurgical

properties including: Various types of cold and hot work tool steels, austenitic, martensitic and ferritic stainless steels and super alloys and … Having produced 130 grades of alloy steel, Esfarayen Industrial Complex has so far managed to provide the technical

knowledge of these products. Quality Control Unit: Quality testing and control process in this complex is performed based on validated standards in the world, including DIN-ISO-ASTM-SEP-EN and other standards required by customers. In all manufacturing processes,

this unit controls the production line based on the prescribed instructions, and based on the product type and standards and customer demands, it has the capability of hardness testing, visual and dimensional inspections, ultrasonic, magnetic particle and

penetrant testing by trained and qualified personnel with valid international certificates. This complex issues Quality Certification for all of its products in accordance with standard EN 10204. Laboratory Unit: Testing and Calibration Laboratories Unit:

The set of Quantumetry, Mechanical Properties, Metallography, Wet Chemistry, and the Calibration and Instruments laboratories offer services in the fields of determination of chemical analysis, determination of gaseous elements, determination of tensile strength,

impact resistance, hardenability, structure, grain size, impurity level , and control of Ferro Alloys and slag analysis in addition to conducting tests associated with the company’s products, and presenting it to the quality control unit. These labs are also

ready to offer testing and calibration services to the customers outside the company. Having accreditation certificate from the Institute of Standards and Industrial Research of Iran along with control and calibration of the equipment affecting the company’s

quality, calibration laboratory is ready to provide calibration services to the customers outside the company. In order to validate and guarantee the quality of testing and calibration results, Esfarayen industrial complex has implemented Standard ISO / IEC

17025 in its testing and calibration laboratories. Quality Assurance Unit: Having improved its capabilities in producing alloy steels, Esfarayen industrial complex has cared about the establishment of new management systems and use of the following new management

assessment tools for establishment and control of quality management system, care about the human health, and environmental and natural resources protection and has succeed to establish the following management systems. Quality Management System ISO 9001-2008

Environmental Management System ISO 14001-2004 Occupational Health and Safety Management System OHSSAS 18001-2007 Lab Management System ISO 17025 Energy Management System MSE 2000, EN16001, ISO 50001-2010 Obtaining the EFQM Excellence Model 3-star level certification

from Iranian National Productivity and Excellence (INPE) Award process

activity as a full manufacturing process from 2005 through full utilization of various production units, including melting and expendable casting unit, radial forge and heavy press unit, heating and heat treatment unit, and heavy and light machining unit.

This complex will offer its capabilities more than ever in the near future through establishing continuous casting lines, Electro Slag Remelting (ESR) production line, machining and heat treatment of super heavy parts. Steelmaking unit: Special alloy steel

production requires advanced equipment and processes that could produce homogeneous steel, clear in terms of the presence of non-metallic inclusions, with lowest value of the unwanted elements such as sulfur, phosphorus, and also the least amount of gas. Therefore,

melting and casting workshop of the complex has been designed and implemented to prepare high-quality alloy steel ingots including melting, secondary metallurgy and ingot casting processes . •The main equipment of this unit includes: 1.Electric Arc Furnace

(EAF) with EBT system and a capacity of 50 tons and capable of blowing oxygen and carbon to produce low phosphorus steel 2.Ladle furnace ( LF ) with a capacity of 50 tons and Argon bottom-blowing system with high purity for flotation and removal of melt impurities

and desulfurization. 3.VD System ( Vacuum degasing ) with a capacity of 50 tons for melt degasing under vacuum of 2mbar and production of steels with: H <1.5ppm N <60PPM O <50PPM S <8PPM 4.VOD System ( Vacuum Oxygen Decaburization ): for production of alloy

steels (Stainless Steel) with c<0.03% 5.VSD ( Vacuum Stream Degasing ): vacuum stream casting to produce ultra-heavy ingots of 50t, 80t and 120t 6.Ingot casting capable of producing alloy ingots of 2.2t to 120t 7.Alloy steel casting line up to 100 tons Radial

Forge Unit Forging production line has been designed to produce specific alloy steel products with high quality and mechanical properties. An important advantage of radial forging process is the ability to work at low tolerances and consequently, greater efficiency,

which is very considerable in case of special steels and superalloys. This line is equipped with five radial forge machines from GFM Company (Austria) which will be able to produce different types of alloy steels with various sections, including round, square,

rounded corner square (RCS ), hexagon, octagon, conical, thick wall and stepped pipes with required metallurgical controls. The main equipment of the workshop includes: •Radial forging machine SXP-65, maximum turning diameter of 650mm •Radial forging machine

SXP-25, maximum turning diameter of 250mm •Radial forging machine SXP-13, maximum turning diameter of 130mm •Radial forging machine SXP-10, maximum turning diameter of 100mm •Radial forging machine SHP-06, maximum turning diameter of 60mm •5 preheating furnaces

•5 heat treatment furnaces, for annealing, normalizing , quenching and tempering heat treatments •Workshop heavy and light transportation equipment Due to the unique specifications of this equipment, it is able to produce a variety of grades of cold work tool,

hot work tool, plastic mold and stainless steel (austenitic, martensitic, ferritic and precipitation hardening). Production capacity of the plant is 48 thousand tons per year. Open Die Press production line Forging operations of large steel sections require

special and unique technology. In sections with diameter of above 500 mm, forging and transforming ingots require a great power, due to their high strength and weigh. Thus, to provide self-sufficiency and exports in production of large wrought alloy parts

and sections in the country, Heavy-Duty Press Workshop of this complex have been implemented through installation of a hydraulic press machine with a power capacity of 6,300 tons (SKODA Company from Czech Republic) and other equipment. •This equipment can

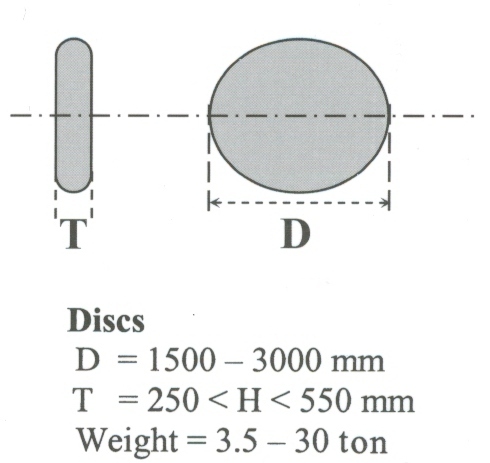

produce a variety of round, square, slab, and stepped sections, and heavy-duty rollers, power plant shafts, ring, disk and thick-walled pipes in various alloy steels. Also, this machine is capable of forging parts up to weight of 120 tons and according to

the mentioned characteristics, the capability of the device is exclusive in the Middle East and is able to supply a part of regional requirements. The main equipment of the workshop includes: •Two-column hydraulic press with a power of 6300 tons •Manipulator

of 80 tons •5 preheating furnaces up to 5 tons •5 heat treatment furnaces up to 120 tons •Workshop heavy and light transportation equipment up to weigh of 150 tons •Flame cutting up to 1500 mm diameter Production capacity of this workshop is 48 thousand tons

per year. Heat treatment line This line includes several different types of heat treatment furnaces up to a capacity of 120 in which various cycles of annealing, normalizing, quenching and tempering heat treatments will be applied to the parts (through immersion

method) to obtain the mechanical properties and microstructure commensurate with world standards and customer demands. The existing reservoirs containing oil and water in this line along with high speed cranes and lifting tools, are able to apply various quench

heat treatments up to weighs about 100 tons to the parts. The furnace with proper temperature tolerance and equipped with accurate thermocouples ensures the achievement of appropriate structure and properties of products after heat treatment. Also, the development

plan of using polymer quenching environment for heat treatment of various high alloy steels has been predicted in supplementary plan of this complex which will be added to the abilities of the complex in the near future. Machining unit: Having Turning, CNC

and Milling machines in different sizes along with Deep Hole Drilling equipments, this unit has the ability to offer products as rough turning and accurate turning. This complex designs and controls the production of high quality products via following technical

support units. Engineering and Research Unit This unit is responsible for designing, reviewing, confirming and validation of the complex manufacturing processes, management of technical knowledge and research and development (R & D) of the following products:

1 - Steel Parts with complexity in terms of the product shape, chemical compound, or both; these parts include: Various types of backup rolls and work rolls in roll industries, drilling bits, conical shafts of mining Stone Breaker Machines, a variety of thick-walled

pipes with application in the fields of oil, gas and petrochemicals, adapter and various high-dimensional rings, for - high-dimensional slabs, various high-diameter discs and ... 2 – Parts with high complexity of chemical compounds and the expected metallurgical

properties including: Various types of cold and hot work tool steels, austenitic, martensitic and ferritic stainless steels and super alloys and … Having produced 130 grades of alloy steel, Esfarayen Industrial Complex has so far managed to provide the technical

knowledge of these products. Quality Control Unit: Quality testing and control process in this complex is performed based on validated standards in the world, including DIN-ISO-ASTM-SEP-EN and other standards required by customers. In all manufacturing processes,

this unit controls the production line based on the prescribed instructions, and based on the product type and standards and customer demands, it has the capability of hardness testing, visual and dimensional inspections, ultrasonic, magnetic particle and

penetrant testing by trained and qualified personnel with valid international certificates. This complex issues Quality Certification for all of its products in accordance with standard EN 10204. Laboratory Unit: Testing and Calibration Laboratories Unit:

The set of Quantumetry, Mechanical Properties, Metallography, Wet Chemistry, and the Calibration and Instruments laboratories offer services in the fields of determination of chemical analysis, determination of gaseous elements, determination of tensile strength,

impact resistance, hardenability, structure, grain size, impurity level , and control of Ferro Alloys and slag analysis in addition to conducting tests associated with the company’s products, and presenting it to the quality control unit. These labs are also

ready to offer testing and calibration services to the customers outside the company. Having accreditation certificate from the Institute of Standards and Industrial Research of Iran along with control and calibration of the equipment affecting the company’s

quality, calibration laboratory is ready to provide calibration services to the customers outside the company. In order to validate and guarantee the quality of testing and calibration results, Esfarayen industrial complex has implemented Standard ISO / IEC

17025 in its testing and calibration laboratories. Quality Assurance Unit: Having improved its capabilities in producing alloy steels, Esfarayen industrial complex has cared about the establishment of new management systems and use of the following new management

assessment tools for establishment and control of quality management system, care about the human health, and environmental and natural resources protection and has succeed to establish the following management systems. Quality Management System ISO 9001-2008

Environmental Management System ISO 14001-2004 Occupational Health and Safety Management System OHSSAS 18001-2007 Lab Management System ISO 17025 Energy Management System MSE 2000, EN16001, ISO 50001-2010 Obtaining the EFQM Excellence Model 3-star level certification

from Iranian National Productivity and Excellence (INPE) Award process