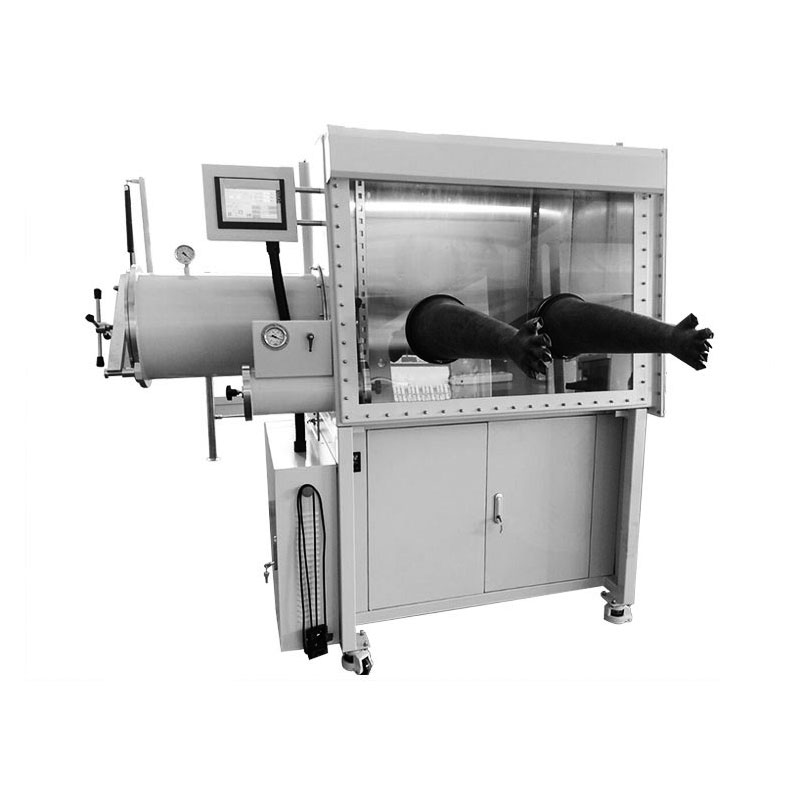

Circulating Purification Glove Box (water and oxygen content below 1ppm) for Lithium Ion Battery

Working principle of circulating purification glove box: The box of the operation box and the gas circulation purification system constitute a tight working space. First, ** gas (such as argon or nitrogen) is introduced into the cabinet to drive away harmful components (such as oxygen molecules and ...

Working principle of circulating purification glove box: The box of the operation box and the gas circulation purification system constitute a tight working space. First, ** gas (such as argon or nitrogen) is introduced into the cabinet to drive away harmful components (such as oxygen molecules and water molecules) in the cabinet. This process is commonly known as "washing gas". The gas in the cabinet is further processed by a circulating purification system to remove traces of harmful components (such as water, oxygen, organic solvents and other active materials), so that the water and oxygen content in the operation box reaches 1 ppm or less.

1) Water content <1ppm ( Under normal conditions, empty container operation can reach 0.1ppm)

2) Oxygen content <1ppm ( Under normal conditions, empty container operation can reach 0.1ppm)

3) Leakage rate: <0.005VOL% / H (Currently the internationally accepted glove box leakage rate standard is <0.05VOL% / H. After several years of intensive research by our company and repeated testing and verification in the application process, it is determined The factory inspection standard of the leak rate of the glove box is: <0.005VOL% / H, which means that our company's glove box leak rate cannot reach the inspection standard of <0.005VOL% / H, and cannot be shipped, which is far superior to international standards , The glove box comes with the oxygen method leak rate detection function for user inspection and acceptance)

4) Filling amount of oxygen scavenger: 10 kg

5) Filling capacity of dewatering agent: 16 kg

6) Filling capacity of activated carbon: 6 kg

1) Water content <1ppm ( Under normal conditions, empty container operation can reach 0.1ppm)

2) Oxygen content <1ppm ( Under normal conditions, empty container operation can reach 0.1ppm)

3) Leakage rate: <0.005VOL% / H (Currently the internationally accepted glove box leakage rate standard is <0.05VOL% / H. After several years of intensive research by our company and repeated testing and verification in the application process, it is determined The factory inspection standard of the leak rate of the glove box is: <0.005VOL% / H, which means that our company's glove box leak rate cannot reach the inspection standard of <0.005VOL% / H, and cannot be shipped, which is far superior to international standards , The glove box comes with the oxygen method leak rate detection function for user inspection and acceptance)

4) Filling amount of oxygen scavenger: 10 kg

5) Filling capacity of dewatering agent: 16 kg

6) Filling capacity of activated carbon: 6 kg

| Attribute name | Attribute value |

|---|---|

| Product Features | |

| Color | Silver |

| Standards | According to customer requirements, CE |

| Installation, Training and Setting-up | Video technical support, Online technical support, Product Manual |

| Performance | multi-function, wide application |

| Warranty | 1Year |

| After Sale Services | lifetime |