Alloy Cu - Ni Copper Continuous Casting Machine One Strand 20mm Thickness

PRODUCT DESCRIPTION Alloy Cu - Ni Copper Continuous Casting Machine One Strand 20mm Thickness Alloy Cu - Ni Copper Continuous Casting Machine One Strand 20mm Thickness 0Alloy Cu - Ni Copper Continuous Casting Machine One Strand 20mm Thickness 1Alloy Cu - Ni Copper Continuous Casting Machine One ...

PRODUCT DESCRIPTION

Alloy Cu - Ni Copper Continuous Casting Machine One Strand 20mm Thickness

Alloy Cu - Ni Copper Continuous Casting Machine One Strand 20mm Thickness 0Alloy Cu - Ni Copper Continuous Casting Machine One Strand 20mm Thickness 1Alloy Cu - Ni Copper Continuous Casting Machine One Strand 20mm Thickness 2

Ⅰ.Major Technical Parameters of Equipment:

1 Smelting furnace:

1.1 Total capacity of furnace 5.0T

1.2 Effective capacity of furnace 2.5T

1.3 Furnace voltage 380V

1.4 Furnace power 600KW

1.5 Melting rate 2t/h

1.6 Power factor after compensation: 0.95-1.0

1.7 Number of phases and connection mode of inductor:

Single-phase series-connection

1.8 Rated capacity of transformer:

900KVA water-cooled autotransformer (380V incoming-line, three-phase,

1.9 coil cooling mode: Water-cooling

1.10 Cooling water consumption: 5m3/h

1.11 Maximum temperature of furnace: 1500℃

2 Holding furnace section

2.1 Effective capacity of furnace: 4.0T

2.2 Effective casting capacity: Less than 85 dB

2.3 Rated voltage: 380V

2.4 Rated power : 250KW

2.5 Rated capacity of transformer:

400KVA water-cooled autotransformer

(380V incoming-line, three-phase,

no-load stepped voltage-regulating).

2.6 Power factor after compensation: 0.95-1.0

2.7 Temperature control precision: ±8℃

2.8 Maximum temperature of furnace: 1300℃

2.9 Coil cooling mode:

Water-cooling

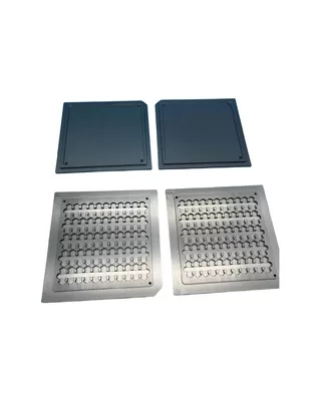

3 Mould

3.1 width 380- 500mm

3.2 thickness 16-20mm.

3.3 Material 1Cr18Ni9Ti stainless steel, lined with copper bush (made of T2 copper)

4 Secondary cooling device

4.1 Water consumption: 3m ³/h

4.2 Water pressure: 0.2-0.3Mpa

5 Withdrawal machine

5.1 Maximum pushing and drawing force: 50KN

5.2 Speed: Speed:

5.3 Minimum stroke range:

0.1mm

5.4 Shortest standby time 0.01S

5.5 AC servo motor: Siemens motor (11KW)

5.6 Rated rotation speed of motor: 3000r/min

5.7 Static torque: △Tw= 60K Mo (at 60) 70N-M

6

Double-billet hydraulic upper shearing machine:

6.1 Shearing force: 600KN

6.2 shearing thickness: 20mm

6.3 Shearing width: 500mm

6.4 Shearing speed:

0- 5mm/s

6.5 Shearing stroke: 80mm

6.6 Maximum follow-up stroke of shearing machine: 200mm

7 Coiler machine unit

7.1 Power: 5.5KW

7.2 Rotational speed: 1420r/min

7.3 Coiler displacement stroke: 800mm

8 Hydraulic station

8.1

Motor power of hydraulic station for smelting furnace and holding furnace:

2× 7.5KW

8.2 Motor power of hydraulic station for withdrawal machine: 2× 7.5KW

8.3 Motor power of hydraulic pump for upper shearing machine:

2× 11KW

8.4 Motor power of hydraulic pump for coiler: 2× 7.5KW

Alloy Cu - Ni Copper Continuous Casting Machine One Strand 20mm Thickness

Alloy Cu - Ni Copper Continuous Casting Machine One Strand 20mm Thickness 0Alloy Cu - Ni Copper Continuous Casting Machine One Strand 20mm Thickness 1Alloy Cu - Ni Copper Continuous Casting Machine One Strand 20mm Thickness 2

Ⅰ.Major Technical Parameters of Equipment:

1 Smelting furnace:

1.1 Total capacity of furnace 5.0T

1.2 Effective capacity of furnace 2.5T

1.3 Furnace voltage 380V

1.4 Furnace power 600KW

1.5 Melting rate 2t/h

1.6 Power factor after compensation: 0.95-1.0

1.7 Number of phases and connection mode of inductor:

Single-phase series-connection

1.8 Rated capacity of transformer:

900KVA water-cooled autotransformer (380V incoming-line, three-phase,

1.9 coil cooling mode: Water-cooling

1.10 Cooling water consumption: 5m3/h

1.11 Maximum temperature of furnace: 1500℃

2 Holding furnace section

2.1 Effective capacity of furnace: 4.0T

2.2 Effective casting capacity: Less than 85 dB

2.3 Rated voltage: 380V

2.4 Rated power : 250KW

2.5 Rated capacity of transformer:

400KVA water-cooled autotransformer

(380V incoming-line, three-phase,

no-load stepped voltage-regulating).

2.6 Power factor after compensation: 0.95-1.0

2.7 Temperature control precision: ±8℃

2.8 Maximum temperature of furnace: 1300℃

2.9 Coil cooling mode:

Water-cooling

3 Mould

3.1 width 380- 500mm

3.2 thickness 16-20mm.

3.3 Material 1Cr18Ni9Ti stainless steel, lined with copper bush (made of T2 copper)

4 Secondary cooling device

4.1 Water consumption: 3m ³/h

4.2 Water pressure: 0.2-0.3Mpa

5 Withdrawal machine

5.1 Maximum pushing and drawing force: 50KN

5.2 Speed: Speed:

5.3 Minimum stroke range:

0.1mm

5.4 Shortest standby time 0.01S

5.5 AC servo motor: Siemens motor (11KW)

5.6 Rated rotation speed of motor: 3000r/min

5.7 Static torque: △Tw= 60K Mo (at 60) 70N-M

6

Double-billet hydraulic upper shearing machine:

6.1 Shearing force: 600KN

6.2 shearing thickness: 20mm

6.3 Shearing width: 500mm

6.4 Shearing speed:

0- 5mm/s

6.5 Shearing stroke: 80mm

6.6 Maximum follow-up stroke of shearing machine: 200mm

7 Coiler machine unit

7.1 Power: 5.5KW

7.2 Rotational speed: 1420r/min

7.3 Coiler displacement stroke: 800mm

8 Hydraulic station

8.1

Motor power of hydraulic station for smelting furnace and holding furnace:

2× 7.5KW

8.2 Motor power of hydraulic station for withdrawal machine: 2× 7.5KW

8.3 Motor power of hydraulic pump for upper shearing machine:

2× 11KW

8.4 Motor power of hydraulic pump for coiler: 2× 7.5KW