Single Shot Injection Molding Services For Medical Equipment Housing

Medical Equipment Housing Injection Mold / Injection Molding Service / Single Shot Mold Injection Molding Service Quick detail: We design tooling and make tooling for clients and also we make customized injection molding components for clients.. We especially good at OEM products development and...

Medical Equipment Housing Injection Mold / Injection Molding Service / Single Shot Mold

Injection Molding Service Quick detail:

We design tooling and make tooling for clients and also we make customized injection molding components for clients..

We especially good at OEM products development and production.

Injection Molding Service / Injection Mold Description:

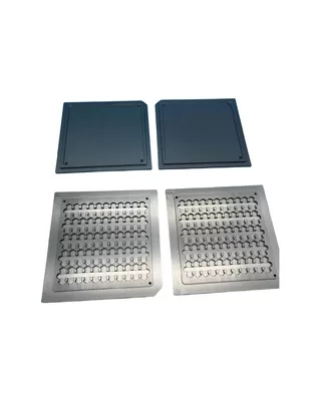

What is the most important of the injection molding service? it is the injection mold,it is the heart of injection molding service, the injection mold includes Tooling Base, Core and Cavities, Ejection systems, Cooling systems etc.. please see below image,

And the most important of injection mold is material choose, Mold design, high accurate tooling make etc..

With our so many years' experience, we can provide our client very high quality injection mold and injection molding service

Single Shot Injection Molding Services For Medical Equipment Housing

Design and production flow:

STEP Process

1 First imput → Receive client's 2D and 3D drawing, better in .step file format, or receive client

2 DFM anaylis on the 3D drawing, Part line, core and cavity design

3 Communication with clients re the DFM anaylis

4 Tooling design and tooling plan

5 Tooling making such as cnc machining and EDM process, tooling assembly etc..

6 First tiral on the tooling,Tooling anaylis after the first trial, OTS checking.

7 Tooling etching or final polishing after First samples approval.

8 Golden samples Trial and samples approval.

9 Pilot production and mass production

Competitive Advantage:

1- 13 Years OEM and ODM experience in plastic injection molding service. One stop tooling room and clean injection workshop.

2. All injection machine with controlled system robot,

2- Advanced equipment and professional technology: CNC, 2D, 2.5D and injection machines.

3- Advanced R&D service and Best Engineer: DFM and Mold Flow Analysis.

4- Excellent and Nice Dual shot injection molding technology,

5- Quality and Price: Quality-oriented and cost drivers analysis to share cost reduction with customers.

6- Series service of design, prototyping, paining, printing and assembly( several assembly lines and one clean assemlby room for finished products)

Injection Molding Service Quick detail:

We design tooling and make tooling for clients and also we make customized injection molding components for clients..

We especially good at OEM products development and production.

Injection Molding Service / Injection Mold Description:

What is the most important of the injection molding service? it is the injection mold,it is the heart of injection molding service, the injection mold includes Tooling Base, Core and Cavities, Ejection systems, Cooling systems etc.. please see below image,

And the most important of injection mold is material choose, Mold design, high accurate tooling make etc..

With our so many years' experience, we can provide our client very high quality injection mold and injection molding service

Single Shot Injection Molding Services For Medical Equipment Housing

Design and production flow:

STEP Process

1 First imput → Receive client's 2D and 3D drawing, better in .step file format, or receive client

2 DFM anaylis on the 3D drawing, Part line, core and cavity design

3 Communication with clients re the DFM anaylis

4 Tooling design and tooling plan

5 Tooling making such as cnc machining and EDM process, tooling assembly etc..

6 First tiral on the tooling,Tooling anaylis after the first trial, OTS checking.

7 Tooling etching or final polishing after First samples approval.

8 Golden samples Trial and samples approval.

9 Pilot production and mass production

Competitive Advantage:

1- 13 Years OEM and ODM experience in plastic injection molding service. One stop tooling room and clean injection workshop.

2. All injection machine with controlled system robot,

2- Advanced equipment and professional technology: CNC, 2D, 2.5D and injection machines.

3- Advanced R&D service and Best Engineer: DFM and Mold Flow Analysis.

4- Excellent and Nice Dual shot injection molding technology,

5- Quality and Price: Quality-oriented and cost drivers analysis to share cost reduction with customers.

6- Series service of design, prototyping, paining, printing and assembly( several assembly lines and one clean assemlby room for finished products)