Multi-Piece Plasma Enhanced Atomic Layer Deposition System for The Deposition of Thin Films of Temperature-Sensitive Materials

The PEALD-B plasma-enhanced atomic layer deposition system is a multi-chip deposition system specially designed for scientific research and industrial development users in special application fields. The electrical system of the system is fully compliant with CE standards; this system extends the co...

The PEALD-B plasma-enhanced atomic layer deposition system is a multi-chip deposition system specially designed for scientific research and industrial development users in special application fields. The electrical system of the system is fully compliant with CE standards; this system extends the common atomic layer deposition system to precursors The selection range of the source, increase the film deposition rate and reduce the deposition temperature, are widely used in the deposition of temperature-sensitive materials and films on flexible substrates.

Product advantages:

Advanced software control system: The system integrates functions such as process recipe, parameter setting, authority setting, interlocking alarm, and status monitoring;

Technical index:

The size of the substrate is 8 inches and below

The substrate heating temperature: room temperature~500℃, control accuracy ±0.1℃

Precursor transport system Standard 3-way precursor pipeline, optional

Precursor pipeline temperature: room temperature~200℃, control accuracy ±0.1℃

Heating temperature of source bottle: room temperature~200℃, control accuracy ±0.1℃

ALD valve Swagelok fast high temperature ALD special valve

Background vacuum <5*10-5Torr, imported anticorrosive pump

Carrier gas system N2 or Ar

Processing capacity 500 pieces of 8 inches

Growth mode High-speed deposition mode and dwell growth mode

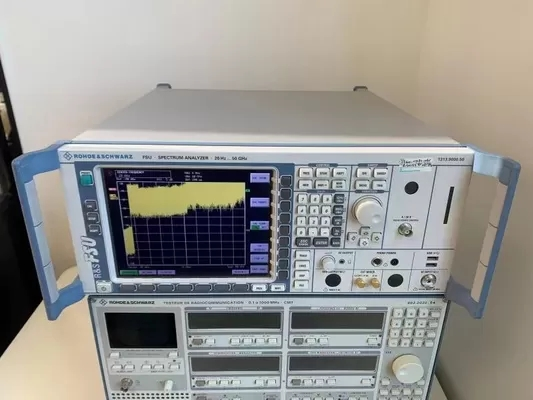

Plasma source 300W inductively coupled remote plasma

Plasma discharge gas source Standard 3 channels, optional

Control system PLC+touch screen or display

Power supply 50-60Hz, 220V/20A AC power supply

Non-uniformity of deposition Non-uniformity<±1%

Equipment size 1300mm x 800mm x 1000mm

Types of deposited films:

Elementary substance: Co, Cu, Ta, Ti, W, Ge, Pt, Ru, Ni, Fe...

Nitride: TiN, SiN, AlN, TaN, ZrN, HfN, WN…

Oxide: TiO2, HfO2, SiO2, ZnO, ZrO2, Al2O3, La2O3, SnO2...

Other compounds: GaAs, AlP, InP, GaP, InAs, LaHfxOy, SrTiO3, SrTaO6...

ALD application examples:

High-K gate oxide layer, storage capacitive dielectric, high aspect ratio diffusion barrier in copper interconnection, pinhole-free passivation layer for OLED, high uniform coating of MEMS, nanoporous structure coating, special fiber doping, solar cell, flat panel Displays, optical films, and other types of nano films with special structures

Product advantages:

Advanced software control system: The system integrates functions such as process recipe, parameter setting, authority setting, interlocking alarm, and status monitoring;

Technical index:

The size of the substrate is 8 inches and below

The substrate heating temperature: room temperature~500℃, control accuracy ±0.1℃

Precursor transport system Standard 3-way precursor pipeline, optional

Precursor pipeline temperature: room temperature~200℃, control accuracy ±0.1℃

Heating temperature of source bottle: room temperature~200℃, control accuracy ±0.1℃

ALD valve Swagelok fast high temperature ALD special valve

Background vacuum <5*10-5Torr, imported anticorrosive pump

Carrier gas system N2 or Ar

Processing capacity 500 pieces of 8 inches

Growth mode High-speed deposition mode and dwell growth mode

Plasma source 300W inductively coupled remote plasma

Plasma discharge gas source Standard 3 channels, optional

Control system PLC+touch screen or display

Power supply 50-60Hz, 220V/20A AC power supply

Non-uniformity of deposition Non-uniformity<±1%

Equipment size 1300mm x 800mm x 1000mm

Types of deposited films:

Elementary substance: Co, Cu, Ta, Ti, W, Ge, Pt, Ru, Ni, Fe...

Nitride: TiN, SiN, AlN, TaN, ZrN, HfN, WN…

Oxide: TiO2, HfO2, SiO2, ZnO, ZrO2, Al2O3, La2O3, SnO2...

Other compounds: GaAs, AlP, InP, GaP, InAs, LaHfxOy, SrTiO3, SrTaO6...

ALD application examples:

High-K gate oxide layer, storage capacitive dielectric, high aspect ratio diffusion barrier in copper interconnection, pinhole-free passivation layer for OLED, high uniform coating of MEMS, nanoporous structure coating, special fiber doping, solar cell, flat panel Displays, optical films, and other types of nano films with special structures

| Attribute name | Attribute value |

|---|---|

| Product Features | |

| Color | Silver, Golden gray |

| Measurement method | Vacuum gauge, Temperature controller |

| Performance | automatic, multi-function, wide application, High precision |

| Standards | According to customer requirements, CE |

| Warranty | 1Year |

| After Sale Services | lifetime |