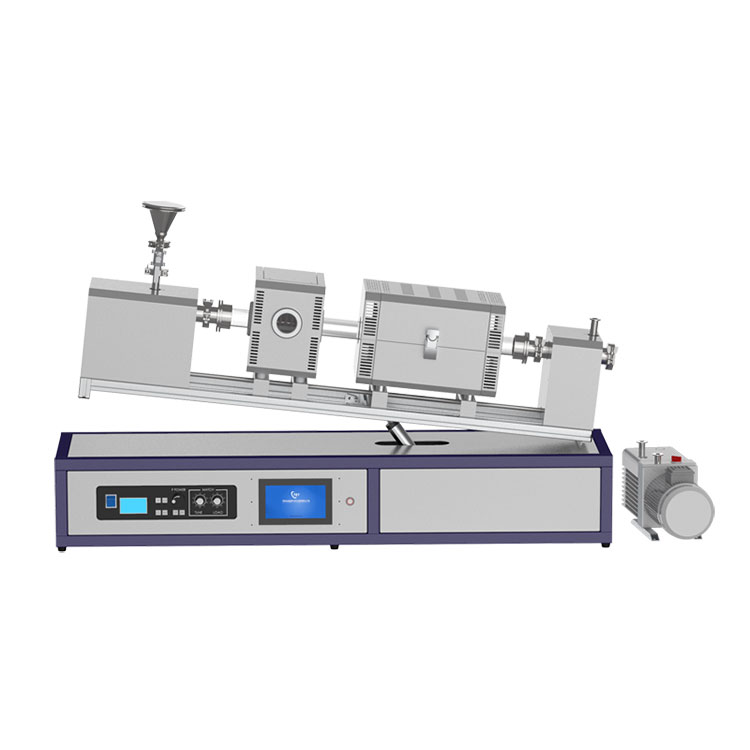

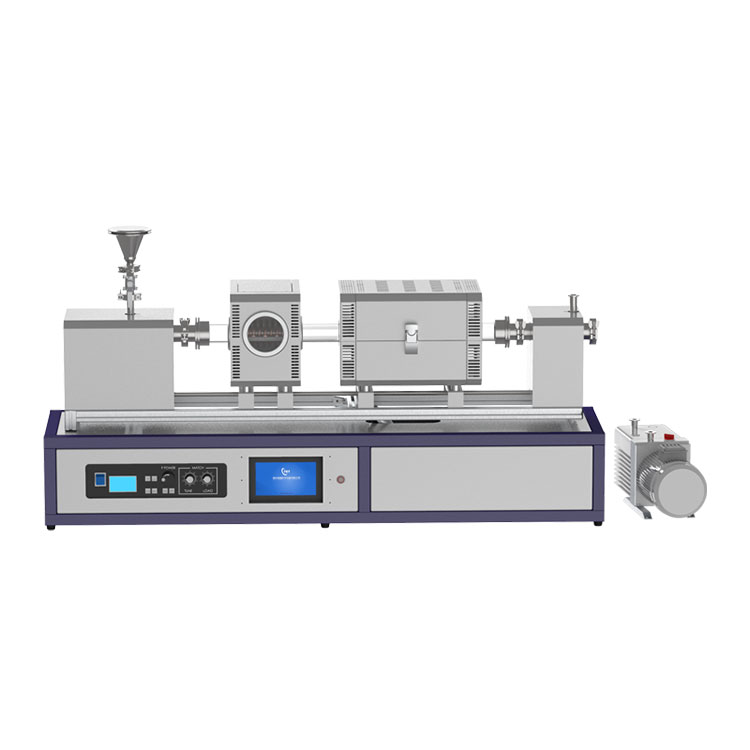

360 Continuous Rotating Plasma Enhanced CVD System Used for Granular Sample Experiment

Product description of Rotating PECVD system Single heating zone rotary PECVD, equipped with vacuum automatic feeder, and KF40 interface reserved at the end of the furnace tube can be connected to the receiving tank. The feeder adopts screw feeding, the powder can be fed into the furnace tube at a ...

Product description of Rotating PECVD system

Single heating zone rotary PECVD, equipped with vacuum automatic feeder, and KF40 interface reserved at the end of the furnace tube can be connected to the receiving tank. The feeder adopts screw feeding, the powder can be fed into the furnace tube at a rated rate, and the feeding rate can be changed by adjusting the rotary speed. It can realize the continuous coating and modification of powder materials by PECVD method under the atmosphere protection environment. The receiving tank can collect the processed powder under the atmosphere protection environment.

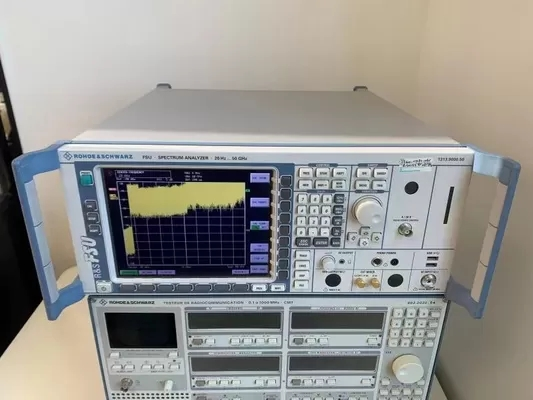

The equipment is equipped with 100W RF power at 13.56MHz. It can generate plasma in vacuum. High-energy plasma can activate the sample surface, effectively enhance the reaction effect and increase the reaction rate. This auxiliary method is widely used in scientific experiments such as graphene preparation and particle coating.

This equipment is especially suitable for granular sample experiments. Through mechanical transmission, it can control the continuous rotation of the working tube 360° with adjustable rotation speed, so that the materials in the tube are continuously stirred and mixed, and fully contact with the gas and plasma, so that the reaction of the sample is more uniform and stable.

Technical parameters of Rotating PECVD system

RF power supply Output Power 150W

Output accuracy ±1%

RF frequency 13.56MHz

RF stability ±0.005%

Cooling method Air-cooling

1200ºC Single heating zone tube furnace Supply voltage AC220V,50Hz

Maximum power 2KW

Heating zone Single heating zone 200mm

Working temperature Maximum 1200 ºC, continuous operating temperature should be ≤1100 ºC

Temperature accuracy ± 1 ºC

Temperature control method AI-PID 30-stage process curve, can store multiple

Three temperature zone independent control, with overheat and thermocouple failure protection

Furnace tube material High purity quartz

Furnace tube size Dia. 50x800mm

Sealing method Vacuum stainless steel flange, KF16 flange

Adjustable speed 0-20rpm

slope 0-15°

Vacuum pump Rotary vane mechanical pump

Ultimate vacuum 1.0E-1Pa

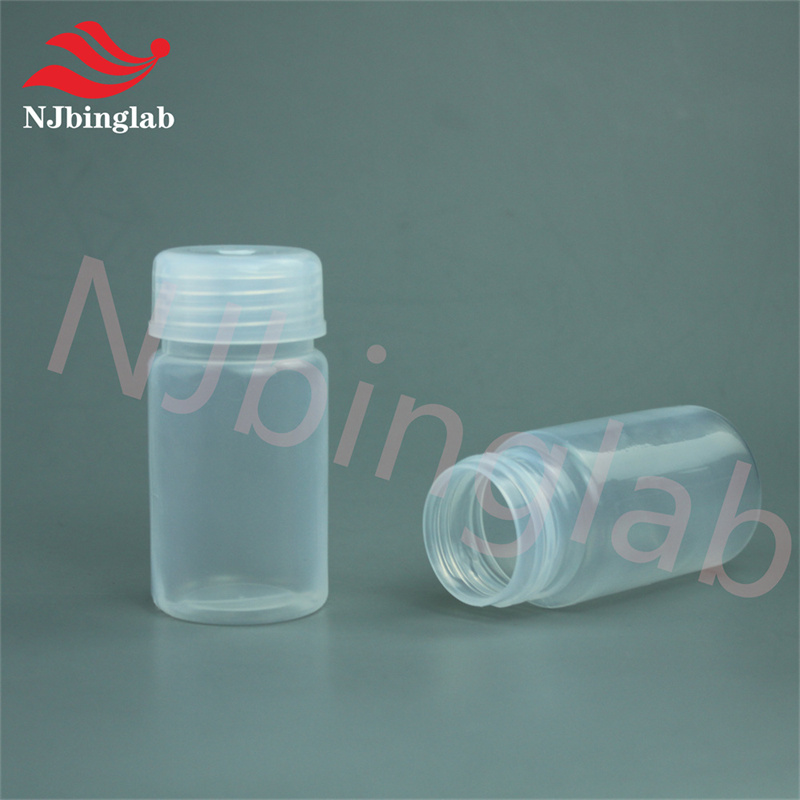

Feeding method Vacuum funnel and screw feed

Single heating zone rotary PECVD, equipped with vacuum automatic feeder, and KF40 interface reserved at the end of the furnace tube can be connected to the receiving tank. The feeder adopts screw feeding, the powder can be fed into the furnace tube at a rated rate, and the feeding rate can be changed by adjusting the rotary speed. It can realize the continuous coating and modification of powder materials by PECVD method under the atmosphere protection environment. The receiving tank can collect the processed powder under the atmosphere protection environment.

The equipment is equipped with 100W RF power at 13.56MHz. It can generate plasma in vacuum. High-energy plasma can activate the sample surface, effectively enhance the reaction effect and increase the reaction rate. This auxiliary method is widely used in scientific experiments such as graphene preparation and particle coating.

This equipment is especially suitable for granular sample experiments. Through mechanical transmission, it can control the continuous rotation of the working tube 360° with adjustable rotation speed, so that the materials in the tube are continuously stirred and mixed, and fully contact with the gas and plasma, so that the reaction of the sample is more uniform and stable.

Technical parameters of Rotating PECVD system

RF power supply Output Power 150W

Output accuracy ±1%

RF frequency 13.56MHz

RF stability ±0.005%

Cooling method Air-cooling

1200ºC Single heating zone tube furnace Supply voltage AC220V,50Hz

Maximum power 2KW

Heating zone Single heating zone 200mm

Working temperature Maximum 1200 ºC, continuous operating temperature should be ≤1100 ºC

Temperature accuracy ± 1 ºC

Temperature control method AI-PID 30-stage process curve, can store multiple

Three temperature zone independent control, with overheat and thermocouple failure protection

Furnace tube material High purity quartz

Furnace tube size Dia. 50x800mm

Sealing method Vacuum stainless steel flange, KF16 flange

Adjustable speed 0-20rpm

slope 0-15°

Vacuum pump Rotary vane mechanical pump

Ultimate vacuum 1.0E-1Pa

Feeding method Vacuum funnel and screw feed

| Attribute name | Attribute value |

|---|---|

| Product Features | |

| Color | Silver |

| Performance | automatic, multi-function, wide application, High precision, Precise temperature control |

| Standards | According to customer requirements, CE |

| Installation, Training and Setting-up | Video technical support, Online technical support, Product Manual |

| Warranty | 1Year |

| After Sale Services | lifetime |