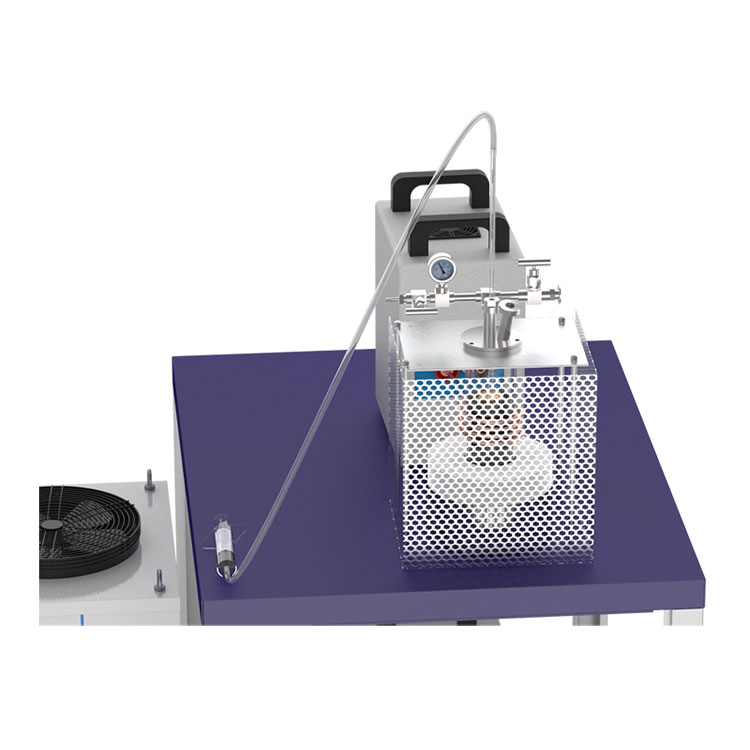

15KW induction heating / melting system with vacuum suction casting device on the top

CY-IMF-15VSC upper suction casting induction melting furnace is a 15KW induction heating / melting system with MET quality certification and vacuum suction casting device on the top. This unique structural design casts the product (3-5mm diameter alloy rod) by drawing molten metal directly into the ...

CY-IMF-15VSC upper suction casting induction melting furnace is a 15KW induction heating / melting system with MET quality certification and vacuum suction casting device on the top. This unique structural design casts the product (3-5mm diameter alloy rod) by drawing molten metal directly into the top quartz tube. The suction force applied by the vacuum suction casting device can make the melt move quickly to quickly solidify the melt in the quartz tube. This set of equipment adopts suction casting method to cast alloy, which can effectively reduce alloy shrinkage defects, and is an ideal tool for preparing small diameter alloy rods.

Technical Parameters

1. Induction heater

Working voltage: 220V AC, 50 / 60Hz single phase; working current: 34A (maximum 40A)

* Large shock power: 15KW; * Large input power: 7KW Output frequency: 30 ~ 80Hz (adjustable); Duty ratio: 80%

Induction coil size: 70mm (OD) × 65mm (ID) × 80mm (H)

Automatic heating time: 1 ~ 99s; Automatic constant temperature time: 1 ~ 99s; Automatic cooling time: 1 ~ 99s

Air cooling: rear fan; protection: automatic water pressure, over temperature and over power protection

2. Vacuum suction casting

The top suction casting device can produce alloy rods with a length of 150mm and a diameter of 3 to 5mm using suction

Using this suction casting method can effectively reduce alloy shrinkage defects

Suction is generated by the rapid movement of the syringe piston (manual operation)

The observation window (Φ12) of the top flange can monitor the melt condition

The quartz tube (7mmOD) × 4mmID × 500mmL) is inserted through the top armor opening for suction casting.

Warning: The temperature of casting alloy should be ﹤ 1200 ℃, so as not to damage the quartz feed tube

3. Graphite crucible & refractory liner & protective cover

The complete refractory liner (5mm thick) made of alumina, including the bottom crucible support, crucible and cover plate.

Include 1.5 ″ OD × 1.25 ″ ID × 3.75 ″ (Deep) graphite crucible

Boron nitride crucible (30 O.D × 24 I.D × 26 H mm) can be provided upon request.

4. Sealing flange & quartz cavity

Stainless steel flange with high temperature silicone O-ring and self-tightening structure

Two needle valves and vacuum gauges are installed on the flange.

Including semi-open quartz tube with dimensions of 60mm (OD) × 52mm (ID) × 225mm (L)

KF25 connector and 1000mm long bellows are connected to the vacuum pump

For safety reasons, the safety valve design control pressure ≤0.02MPa

5. Water cooler

Temperature range: 2 ~ 35 ℃; water flow: 16L / min

Water tank: 6L in volume, stainless steel

Note: It is recommended to use specific coolant to get the best performance. After several heating tests, it is normal to wait a few minutes for cooling

6. Vacuum pump

A 156L / min two-stage rotary vane vacuum pump is standard.

Vacuum: up to 10E-4 Torr

Voltage: AC 208-240V 50 / 60Hz, single phase; * High power: 4KW

Technical Parameters

1. Induction heater

Working voltage: 220V AC, 50 / 60Hz single phase; working current: 34A (maximum 40A)

* Large shock power: 15KW; * Large input power: 7KW Output frequency: 30 ~ 80Hz (adjustable); Duty ratio: 80%

Induction coil size: 70mm (OD) × 65mm (ID) × 80mm (H)

Automatic heating time: 1 ~ 99s; Automatic constant temperature time: 1 ~ 99s; Automatic cooling time: 1 ~ 99s

Air cooling: rear fan; protection: automatic water pressure, over temperature and over power protection

2. Vacuum suction casting

The top suction casting device can produce alloy rods with a length of 150mm and a diameter of 3 to 5mm using suction

Using this suction casting method can effectively reduce alloy shrinkage defects

Suction is generated by the rapid movement of the syringe piston (manual operation)

The observation window (Φ12) of the top flange can monitor the melt condition

The quartz tube (7mmOD) × 4mmID × 500mmL) is inserted through the top armor opening for suction casting.

Warning: The temperature of casting alloy should be ﹤ 1200 ℃, so as not to damage the quartz feed tube

3. Graphite crucible & refractory liner & protective cover

The complete refractory liner (5mm thick) made of alumina, including the bottom crucible support, crucible and cover plate.

Include 1.5 ″ OD × 1.25 ″ ID × 3.75 ″ (Deep) graphite crucible

Boron nitride crucible (30 O.D × 24 I.D × 26 H mm) can be provided upon request.

4. Sealing flange & quartz cavity

Stainless steel flange with high temperature silicone O-ring and self-tightening structure

Two needle valves and vacuum gauges are installed on the flange.

Including semi-open quartz tube with dimensions of 60mm (OD) × 52mm (ID) × 225mm (L)

KF25 connector and 1000mm long bellows are connected to the vacuum pump

For safety reasons, the safety valve design control pressure ≤0.02MPa

5. Water cooler

Temperature range: 2 ~ 35 ℃; water flow: 16L / min

Water tank: 6L in volume, stainless steel

Note: It is recommended to use specific coolant to get the best performance. After several heating tests, it is normal to wait a few minutes for cooling

6. Vacuum pump

A 156L / min two-stage rotary vane vacuum pump is standard.

Vacuum: up to 10E-4 Torr

Voltage: AC 208-240V 50 / 60Hz, single phase; * High power: 4KW

| Attribute name | Attribute value |

|---|---|

| Product Features | |

| Color | Silver |

| Standards | According to customer requirements |

| Installation, Training and Setting-up | Video technical support, Online technical support, Product Manual |

| Performance | multi-function, wide application, High precision |

| Warranty | 1Year |

| After Sale Services | lifetime |