AI PS 100ml heuft bottle inspection Bottle Inspection System Equipment 5.0kw-6.0kw Product Details:

1. Detecting products

100ml PS material plastic bottle products have characteristics such as small density (light), environmental protection, non-toxic, and higher plasticity. However, since the toughness of this material is relatively poor, it is easy to

100ml PS material plastic bottle products have characteristics such as small density (light), environmental protection, non-toxic, and higher plasticity. However, since the toughness of this material is relatively poor, it is easy to

1. Detecting products

100ml PS material plastic bottle products have characteristics such as small density (light), environmental protection, non-toxic, and higher plasticity. However, since the toughness of this material is relatively poor, it is easy to break, so after making a finished product, it is necessary to detect completely the product's appearance to ensure that there will be no packaging issues in the use of the market. The production of general bottles is produced according to the custom needs of brand vendors, so it is necessary to detect the appearance, shape, bottle mouth, bottle body, to check if there are black spots, stains, burrs, foreign objects and other flaws . Keye Tech has a lot of practical cases to the appearance of the bottle body, which can compare the traditional artificial detecting methods, using the latest AI technology visual detection technology to help manufacturers increase production efficiency and save costs.

2. Detection principle

The product is stably ordered to a specific station through the transfer device, and then the high-pixel sample image taken by the industrial camera is transferred to the image processing software, and the standard sample is compared and analyzed to determine the good product and the defective product, and control the corresponding pneumatic to remove the defective products and finally collect the qualified products.

The software will open the sample comparison standard, and the production personnel on the customer site can control the comparison accuracy and choose the accuracy standard most suitable for their own production conditions, thereby controlling the product defect rate.

3, Detecting details

Our design plan adopts 11 sets of high-pixel industrial cameras and high-performance stroboscopic light sources to carry out a full range of visual detection for the appearance defects of the bottle body. The detection speed is 120 pieces per minute. The equipment can realize 7*24 hours of operation, and the unqualified products can be automatically rejected online.

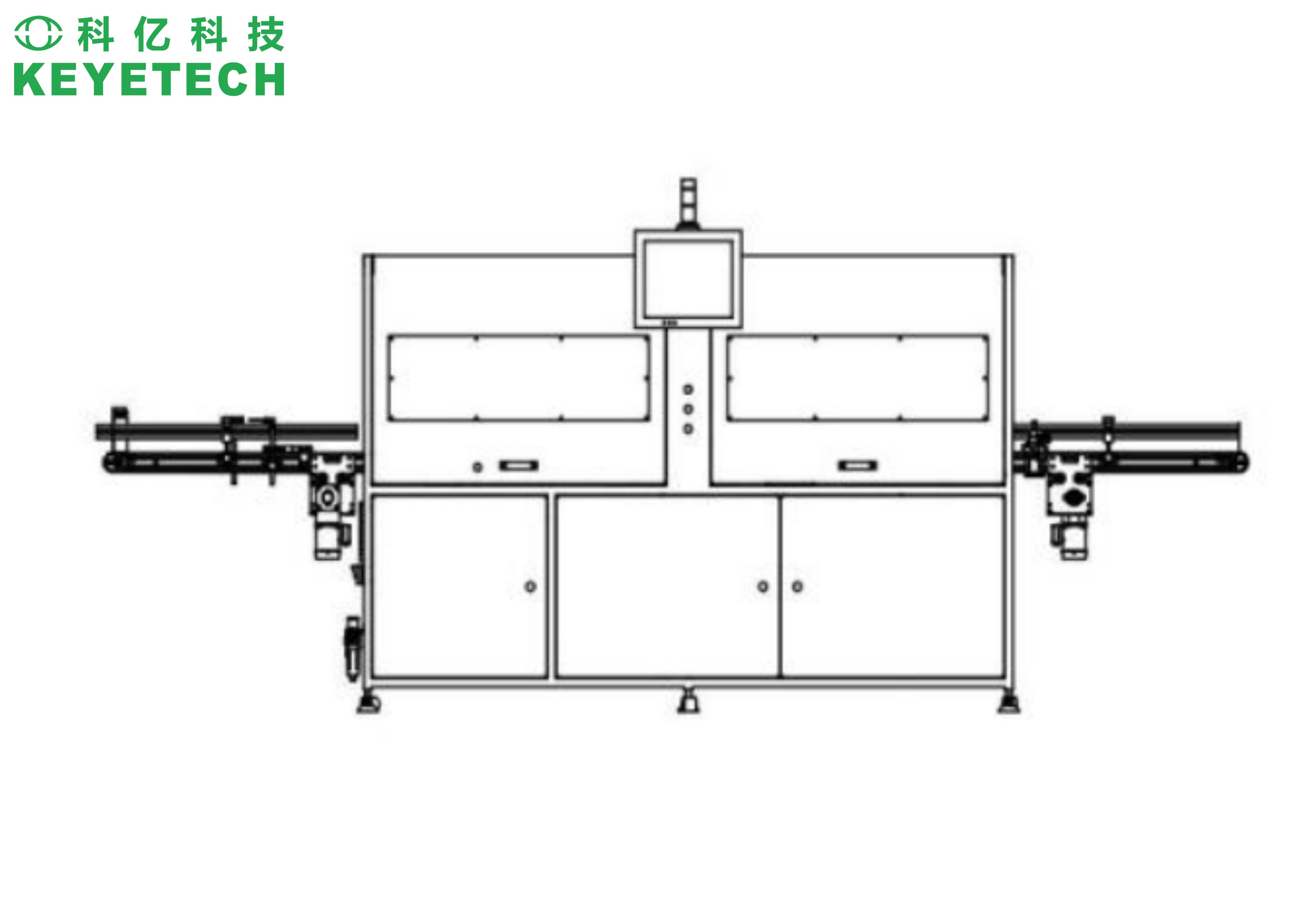

The whole set of detecting equipment includes mechanical parts, visual electronic hardware and detecting system software. The entrance and exit of the detecting machine can be integrated with the on-site conveyor line (see the design drawings for details), and can be connected to the upstream and downstream production equipment according to the specific production needs of the customer.

100ml PS material plastic bottle products have characteristics such as small density (light), environmental protection, non-toxic, and higher plasticity. However, since the toughness of this material is relatively poor, it is easy to break, so after making a finished product, it is necessary to detect completely the product's appearance to ensure that there will be no packaging issues in the use of the market. The production of general bottles is produced according to the custom needs of brand vendors, so it is necessary to detect the appearance, shape, bottle mouth, bottle body, to check if there are black spots, stains, burrs, foreign objects and other flaws . Keye Tech has a lot of practical cases to the appearance of the bottle body, which can compare the traditional artificial detecting methods, using the latest AI technology visual detection technology to help manufacturers increase production efficiency and save costs.

2. Detection principle

The product is stably ordered to a specific station through the transfer device, and then the high-pixel sample image taken by the industrial camera is transferred to the image processing software, and the standard sample is compared and analyzed to determine the good product and the defective product, and control the corresponding pneumatic to remove the defective products and finally collect the qualified products.

The software will open the sample comparison standard, and the production personnel on the customer site can control the comparison accuracy and choose the accuracy standard most suitable for their own production conditions, thereby controlling the product defect rate.

3, Detecting details

Our design plan adopts 11 sets of high-pixel industrial cameras and high-performance stroboscopic light sources to carry out a full range of visual detection for the appearance defects of the bottle body. The detection speed is 120 pieces per minute. The equipment can realize 7*24 hours of operation, and the unqualified products can be automatically rejected online.

The whole set of detecting equipment includes mechanical parts, visual electronic hardware and detecting system software. The entrance and exit of the detecting machine can be integrated with the on-site conveyor line (see the design drawings for details), and can be connected to the upstream and downstream production equipment according to the specific production needs of the customer.

| نام ویژگی | مقدار ویژگی |

|---|---|

| مشخصات محصول | |

| رنگ | سفید |