0.15mm Thickness Polyolefin Hot Melt Adhesive Film Eco Friendly

Ecofriendly 150mic Thickness Polyolefin Hot Melt Adhesive Film Bonding Aluminum Net Drill Accessories to Clothing Description: Polyolefin Hot Melt Adhesive Film is a thermoplastic adhesive product , the raw material is polyolefin, the structure is polyolefin film + release paper,it is suitab...

Ecofriendly 150mic Thickness Polyolefin Hot Melt Adhesive Film Bonding Aluminum Net Drill Accessories to Clothing

Description:

Polyolefin Hot Melt Adhesive Film is a thermoplastic adhesive product , the raw material is polyolefin, the structure is polyolefin film + release paper,it is suitable for wide range of adherend . It can be repeatedly heated for bonding. This adhesive product possesses excellent washability and chemical additives resistant.

Physical Characteristics:

Color Transparent Release Liner Silicone release paper

Density 1.2±0.02g/cm³ Normal Thickness 0.12mm,0.15mm,0.18mm

Melt Flow Index 50±20g/10min

Condition:ASTMD1238-04 Conventional Width 480mm,960mm

Operating Temperature 140℃-160℃ Length 100 yards or as your demands

Operating Time 3-15seconds Flow Beginning Point 90℃

Remarks:The above information and technical support are based on our current knowledgeand experience.They are witout guarantee and legal claim.To obtain the best processing conditions, we suggest customers test the samples before using our products.

0.15mm Thickness Polyolefin Hot Melt Adhesive Film Eco Friendly 0

0.15mm Thickness Polyolefin Hot Melt Adhesive Film Eco Friendly 1

Applications:

Development direction and application of HT01 is for adhesion in garments accessories, footwear, handbags, luggage, embroidery, hot fix, iron logo and crafts .

0.15mm Thickness Polyolefin Hot Melt Adhesive Film Eco Friendly 2

Hot Melt Adhesive Film's Advantages

1. Clean;

2. Envorentment friendly;

3. High efficiency. In the all process, just need a several seconds.

4. Safety. This product is non-solvent and haven't any hidden trouble in your production.

5. Hot melt adhesive film has better fastness than other glue which could be widely used to laminate many materials;

6. Automatic production can be cometure.

7. Portable and easy operattion

8. Reusable. At the film melting,you can use it again and again.

9. Hot melt adhesive film has good dry cleaning, washable, low-temperature resistance, high-temperature resistance and other kinds of good features;

10. Can be used as adhesives and sealants;

Quality Control:

Ecofriendly Thermoplastic Hot Melt Adhesive Film For Bonding UV Plating and Genuine Leather 9 Ecofriendly Thermoplastic Hot Melt Adhesive Film For Bonding UV Plating and Genuine Leather 10 Ecofriendly Thermoplastic Hot Melt Adhesive Film For Bonding UV Plating and Genuine Leather 11

Support Customization Production:

We have many years experience for control the products quality, and we can customize to product as your opinions.According to customer details demands for new product development, we can offer technical support and production as customer opines.Please contact with us for any about the product questions.

1. According to the Film Performance:

A. Melt Point: 70-110℃,

B. Melt Index:10-2000g/10min( Condition:190℃/2.16KG ASTMD1238-04),

C. Thickness:0.05mm-1mm,

D. Width: 5mm-1500mm,

E. Length:1M-1000M/roll,

F.C olors:All of colors

2. According to the base material:

A. Single/Double side silicone glassine release paper,

B. Single/Double side silicone kraft release paper,

C. Single/Double side silicone PE coated paper,

D. Matte / Glossy PP paper,

E. Matte / Glossy Pearlescent paper,

F. Single/Double side silicone PET release film,

G. Without base materials

H. You also can choose the base materials thickness and grammage.

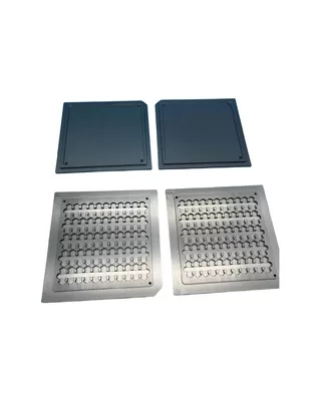

3. Custom Punching Hot Melt Adhesive Film(Support custom as your demands.)

A. Conventional Aperture:1.4mm,1.5mm,1.8mm

B. Conventional Hole Spacing:5mm*5mm or 5.8mm*3.7mm

Milky Translucent 0.03mm Thickness Polyurethane Hot Melt Glue Film For Composite Leater or Textlie Fabrics 11

Description:

Polyolefin Hot Melt Adhesive Film is a thermoplastic adhesive product , the raw material is polyolefin, the structure is polyolefin film + release paper,it is suitable for wide range of adherend . It can be repeatedly heated for bonding. This adhesive product possesses excellent washability and chemical additives resistant.

Physical Characteristics:

Color Transparent Release Liner Silicone release paper

Density 1.2±0.02g/cm³ Normal Thickness 0.12mm,0.15mm,0.18mm

Melt Flow Index 50±20g/10min

Condition:ASTMD1238-04 Conventional Width 480mm,960mm

Operating Temperature 140℃-160℃ Length 100 yards or as your demands

Operating Time 3-15seconds Flow Beginning Point 90℃

Remarks:The above information and technical support are based on our current knowledgeand experience.They are witout guarantee and legal claim.To obtain the best processing conditions, we suggest customers test the samples before using our products.

0.15mm Thickness Polyolefin Hot Melt Adhesive Film Eco Friendly 0

0.15mm Thickness Polyolefin Hot Melt Adhesive Film Eco Friendly 1

Applications:

Development direction and application of HT01 is for adhesion in garments accessories, footwear, handbags, luggage, embroidery, hot fix, iron logo and crafts .

0.15mm Thickness Polyolefin Hot Melt Adhesive Film Eco Friendly 2

Hot Melt Adhesive Film's Advantages

1. Clean;

2. Envorentment friendly;

3. High efficiency. In the all process, just need a several seconds.

4. Safety. This product is non-solvent and haven't any hidden trouble in your production.

5. Hot melt adhesive film has better fastness than other glue which could be widely used to laminate many materials;

6. Automatic production can be cometure.

7. Portable and easy operattion

8. Reusable. At the film melting,you can use it again and again.

9. Hot melt adhesive film has good dry cleaning, washable, low-temperature resistance, high-temperature resistance and other kinds of good features;

10. Can be used as adhesives and sealants;

Quality Control:

Ecofriendly Thermoplastic Hot Melt Adhesive Film For Bonding UV Plating and Genuine Leather 9 Ecofriendly Thermoplastic Hot Melt Adhesive Film For Bonding UV Plating and Genuine Leather 10 Ecofriendly Thermoplastic Hot Melt Adhesive Film For Bonding UV Plating and Genuine Leather 11

Support Customization Production:

We have many years experience for control the products quality, and we can customize to product as your opinions.According to customer details demands for new product development, we can offer technical support and production as customer opines.Please contact with us for any about the product questions.

1. According to the Film Performance:

A. Melt Point: 70-110℃,

B. Melt Index:10-2000g/10min( Condition:190℃/2.16KG ASTMD1238-04),

C. Thickness:0.05mm-1mm,

D. Width: 5mm-1500mm,

E. Length:1M-1000M/roll,

F.C olors:All of colors

2. According to the base material:

A. Single/Double side silicone glassine release paper,

B. Single/Double side silicone kraft release paper,

C. Single/Double side silicone PE coated paper,

D. Matte / Glossy PP paper,

E. Matte / Glossy Pearlescent paper,

F. Single/Double side silicone PET release film,

G. Without base materials

H. You also can choose the base materials thickness and grammage.

3. Custom Punching Hot Melt Adhesive Film(Support custom as your demands.)

A. Conventional Aperture:1.4mm,1.5mm,1.8mm

B. Conventional Hole Spacing:5mm*5mm or 5.8mm*3.7mm

Milky Translucent 0.03mm Thickness Polyurethane Hot Melt Glue Film For Composite Leater or Textlie Fabrics 11