99.7 Alumina Ceramic Crucible Boat Precision Machined Ceramic Parts

Product Description 99% 95% 96% Al2O3 Alumina Ceramic Substrate For LED Pcb Microelectronics 3.93g Cm3 Features 1) A variety of specifications available. 2) Satisfy various technical request 3) Lower medium spoilage 4) Good insulation performance and high temperature resistance 5) Stiffness texture ...

Product Description

99% 95% 96% Al2O3 Alumina Ceramic Substrate For LED Pcb Microelectronics 3.93g Cm3

Features

1) A variety of specifications available.

2) Satisfy various technical request

3) Lower medium spoilage

4) Good insulation performance and high temperature resistance

5) Stiffness texture

6) Used in all electric products, electric heating products and wear resistant machinery parts.

We can supply the products according to customer's drawings, samples and performance requirement. Features

Alumina ceramic performance table

Property

Item

Data

Unit

99.8% 99% 95%

Mechanical Characteristics

color Ivory light yellow White -

density 3.93 3.85 3.7 g/cm3

Bending Strength 370 310 300 MPa

Compressive trength 2,500 2,400 2,300 MPa

Elastic Modulus 390 340 320 GPa

Fracture Toughness 4 3~4 3~4

MPa m^1/2

Weber Coefficient 12 12 12 m

Vickers Hardness 1,850 1,600 1,400 HV 0.5

Thermal Characterics

Coefficient of Line Thermal

Expansion

7~8 7~8 7~8

10^-6 K^-1

Thermal Conductivity

32 29 20

W/mK

Thermal Shock Resistance

(Put in Water)

280 200 250 ΔT °C

Max Working Temperature

1,700 1,600 1,500 °C

Electrical Characteristics

Volume Resistance at 20°C

>10^14 >10^14 >10^14 Ωcm

Dielectric Strength

15×10^6

15×10^6

15×10^6

V/m

Dielectric Constant 10 10 10 εr

One MHZ Dielectric Loss Angle

at 20°C

0.0001

0.0002

0.0004

tanδ

Chemical Characteristics

Nitric Acid (60%) 90°C

0.05 0.1 0.1

WT Loss mg/cm^2/day

Sulphuric Acid (95%) 95°C 0.22 0.34 0.3

Caustic Soda (30%) 80°C

0.04 0.95 0.9

We can provide a variety of high-performance engineering ceramics.

99.7 Alumina Ceramic Crucible Boat Precision Machined Ceramic Parts 0

Silicon Nitride Ceramics (Si3N4)

Silicon nitride exceeds other ceramics in thermal shock resistance. Its strength does not deteriorate at elevated temperatures, hence it is most appropriate for engine and gas turbine parts, including turbo charger rotors, diesel engine glow plugs and hot plugs.

99.7 Alumina Ceramic Crucible Boat Precision Machined Ceramic Parts 1

Alumina Ceramics (Al2O3)

Alumina is the most widely used type of ceramic. Its high dielectric properties are beneficial in electrical products, Alumina offers corrosion and wear resistance and high strength. It is widely used for industrial machine parts.

99.7 Alumina Ceramic Crucible Boat Precision Machined Ceramic Parts 2

Silicon Carbide Ceramic (SiC)

Silicon carbide retains its strength at elevated temperatures as high as 1400℃. It has the highest corrosion resistance of all fine ceramic materials. Applications include mechanical seals and pump parts.

99.7 Alumina Ceramic Crucible Boat Precision Machined Ceramic Parts 3

Zirconia Ceramics (ZrO2)

Zirconia ceramic has the highest strength and toughness at room temperature of all engineering ceramics. Before zirconia, ceramics were considered impractical for scissor or knife applications. With its excellent surface smoothness, zirconia is also used for pump parts.

99.7 Alumina Ceramic Crucible Boat Precision Machined Ceramic Parts 4

Aluminum Nitride Ceramics(AIN)

Aluminum nitride ceramics are usually gray or off-white. It has a low thermal expansion coefficient, excellent insulation performance, heat resistance, and a thermal conductivity of more than 180W/(m.k). It is an ideal package heat dissipation material for large integrated circuits.

99.7 Alumina Ceramic Crucible Boat Precision Machined Ceramic Parts 5

Machinable Glass Ceramic

Machinable glass ceramics are fluorophlogopite mica glass ceramics with synthetic mica as the main crystal phase. The main components are fluorophlogopite and glass with silica as the main component. Contains 55% fluorophlogopite and 45% borosilicate glass matrix.

99.7 Alumina Ceramic Crucible Boat Precision Machined Ceramic Parts 6

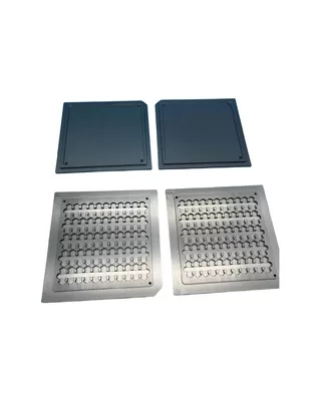

Microporous Ceramic Plate

Microporous ceramics refer to ceramic bodies containing a large number of open or closed tiny pores. The material is mainly alumina or carbonized. The surface is firm, the pores are uniform, the porosity is 35-40%, and the pore size ranges from 1 to 100 microns.

99.7 Alumina Ceramic Crucible Boat Precision Machined Ceramic Parts 7

Boron Nitride(h-BN)

Boron nitride material has the characteristics of resistance to high temperature and heat cycle. It will not react with many metals, ceramic rare earths and other materials, nor will it contaminate the product. Will not break in hot and cold environments.

99.7 Alumina Ceramic Crucible Boat Precision Machined Ceramic Parts 8

Other Ceramics

Our company can process a variety of ceramic materials and cemented carbide. We are currently processing experimental splines for many research institutes and schools. You can provide materials and we can process them according to drawings.

We can provide products according to your drawings or samples and performance requirements.

99.7 Alumina Ceramic Crucible Boat Precision Machined Ceramic Parts 9

Ceramic shaft and sleeve

99.7 Alumina Ceramic Crucible Boat Precision Machined Ceramic Parts 10

Plane processing

99.7 Alumina Ceramic Crucible Boat Precision Machined Ceramic Parts 11

Ceramic micro hole machining

99.7 Alumina Ceramic Crucible Boat Precision Machined Ceramic Parts 12

Ceramic processing thread

99.7 Alumina Ceramic Crucible Boat Precision Machined Ceramic Parts 13

Ceramic complex shaped parts

99.7 Alumina Ceramic Crucible Boat Precision Machined Ceramic Parts 14

Ceramic parts polishing

99% 95% 96% Al2O3 Alumina Ceramic Substrate For LED Pcb Microelectronics 3.93g Cm3

Features

1) A variety of specifications available.

2) Satisfy various technical request

3) Lower medium spoilage

4) Good insulation performance and high temperature resistance

5) Stiffness texture

6) Used in all electric products, electric heating products and wear resistant machinery parts.

We can supply the products according to customer's drawings, samples and performance requirement. Features

Alumina ceramic performance table

Property

Item

Data

Unit

99.8% 99% 95%

Mechanical Characteristics

color Ivory light yellow White -

density 3.93 3.85 3.7 g/cm3

Bending Strength 370 310 300 MPa

Compressive trength 2,500 2,400 2,300 MPa

Elastic Modulus 390 340 320 GPa

Fracture Toughness 4 3~4 3~4

MPa m^1/2

Weber Coefficient 12 12 12 m

Vickers Hardness 1,850 1,600 1,400 HV 0.5

Thermal Characterics

Coefficient of Line Thermal

Expansion

7~8 7~8 7~8

10^-6 K^-1

Thermal Conductivity

32 29 20

W/mK

Thermal Shock Resistance

(Put in Water)

280 200 250 ΔT °C

Max Working Temperature

1,700 1,600 1,500 °C

Electrical Characteristics

Volume Resistance at 20°C

>10^14 >10^14 >10^14 Ωcm

Dielectric Strength

15×10^6

15×10^6

15×10^6

V/m

Dielectric Constant 10 10 10 εr

One MHZ Dielectric Loss Angle

at 20°C

0.0001

0.0002

0.0004

tanδ

Chemical Characteristics

Nitric Acid (60%) 90°C

0.05 0.1 0.1

WT Loss mg/cm^2/day

Sulphuric Acid (95%) 95°C 0.22 0.34 0.3

Caustic Soda (30%) 80°C

0.04 0.95 0.9

We can provide a variety of high-performance engineering ceramics.

99.7 Alumina Ceramic Crucible Boat Precision Machined Ceramic Parts 0

Silicon Nitride Ceramics (Si3N4)

Silicon nitride exceeds other ceramics in thermal shock resistance. Its strength does not deteriorate at elevated temperatures, hence it is most appropriate for engine and gas turbine parts, including turbo charger rotors, diesel engine glow plugs and hot plugs.

99.7 Alumina Ceramic Crucible Boat Precision Machined Ceramic Parts 1

Alumina Ceramics (Al2O3)

Alumina is the most widely used type of ceramic. Its high dielectric properties are beneficial in electrical products, Alumina offers corrosion and wear resistance and high strength. It is widely used for industrial machine parts.

99.7 Alumina Ceramic Crucible Boat Precision Machined Ceramic Parts 2

Silicon Carbide Ceramic (SiC)

Silicon carbide retains its strength at elevated temperatures as high as 1400℃. It has the highest corrosion resistance of all fine ceramic materials. Applications include mechanical seals and pump parts.

99.7 Alumina Ceramic Crucible Boat Precision Machined Ceramic Parts 3

Zirconia Ceramics (ZrO2)

Zirconia ceramic has the highest strength and toughness at room temperature of all engineering ceramics. Before zirconia, ceramics were considered impractical for scissor or knife applications. With its excellent surface smoothness, zirconia is also used for pump parts.

99.7 Alumina Ceramic Crucible Boat Precision Machined Ceramic Parts 4

Aluminum Nitride Ceramics(AIN)

Aluminum nitride ceramics are usually gray or off-white. It has a low thermal expansion coefficient, excellent insulation performance, heat resistance, and a thermal conductivity of more than 180W/(m.k). It is an ideal package heat dissipation material for large integrated circuits.

99.7 Alumina Ceramic Crucible Boat Precision Machined Ceramic Parts 5

Machinable Glass Ceramic

Machinable glass ceramics are fluorophlogopite mica glass ceramics with synthetic mica as the main crystal phase. The main components are fluorophlogopite and glass with silica as the main component. Contains 55% fluorophlogopite and 45% borosilicate glass matrix.

99.7 Alumina Ceramic Crucible Boat Precision Machined Ceramic Parts 6

Microporous Ceramic Plate

Microporous ceramics refer to ceramic bodies containing a large number of open or closed tiny pores. The material is mainly alumina or carbonized. The surface is firm, the pores are uniform, the porosity is 35-40%, and the pore size ranges from 1 to 100 microns.

99.7 Alumina Ceramic Crucible Boat Precision Machined Ceramic Parts 7

Boron Nitride(h-BN)

Boron nitride material has the characteristics of resistance to high temperature and heat cycle. It will not react with many metals, ceramic rare earths and other materials, nor will it contaminate the product. Will not break in hot and cold environments.

99.7 Alumina Ceramic Crucible Boat Precision Machined Ceramic Parts 8

Other Ceramics

Our company can process a variety of ceramic materials and cemented carbide. We are currently processing experimental splines for many research institutes and schools. You can provide materials and we can process them according to drawings.

We can provide products according to your drawings or samples and performance requirements.

99.7 Alumina Ceramic Crucible Boat Precision Machined Ceramic Parts 9

Ceramic shaft and sleeve

99.7 Alumina Ceramic Crucible Boat Precision Machined Ceramic Parts 10

Plane processing

99.7 Alumina Ceramic Crucible Boat Precision Machined Ceramic Parts 11

Ceramic micro hole machining

99.7 Alumina Ceramic Crucible Boat Precision Machined Ceramic Parts 12

Ceramic processing thread

99.7 Alumina Ceramic Crucible Boat Precision Machined Ceramic Parts 13

Ceramic complex shaped parts

99.7 Alumina Ceramic Crucible Boat Precision Machined Ceramic Parts 14

Ceramic parts polishing