Thermoplastic Liquid Acrylic Resinfor Ultra Thin Fire Retardant Coatings

Thermoplastic Acrylic Resins are a class of thermoplastic resins made by polymerizing acrylic acid, methacrylic acid and derivatives thereof such as esters, nitriles, and amides. ELEGANT®A901 is a special acrylic resin for fire retardant coating,it is a new generation of air dry modified acrylic...

Thermoplastic Acrylic Resins are a class of thermoplastic resins made by polymerizing acrylic acid, methacrylic acid and derivatives thereof such as esters, nitriles, and amides.

ELEGANT®A901 is a special acrylic resin for fire retardant coating,it is a new generation of air dry modified acrylic resin, which has good compatibility with Aliphatic Hydrocarbon Solvent. It can effectively improve the indicators of fire retardant coating and provide its effective guarantee, and can also make road marking paint.

Our service

We provide existing product lines as well as custom design capability in meeting the needs of customers

We provide sourcing services for any ancillary products

We provide a high level of customer service and support in conjunction with high quality products at competitive prices

Application

· metal productions

· air dry priming coat

· road marking paint

. fire retardant paint

Markets

· metal productions Industry

. fireproof Industry

. road and concrete construction

General Characteristics

· Appearance (gloss, build)

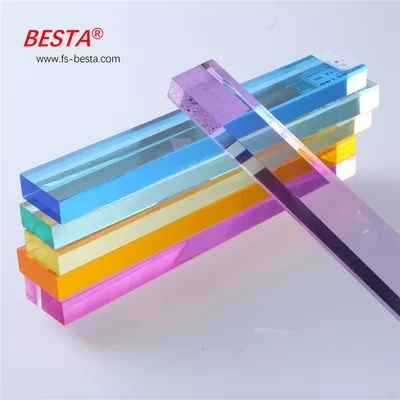

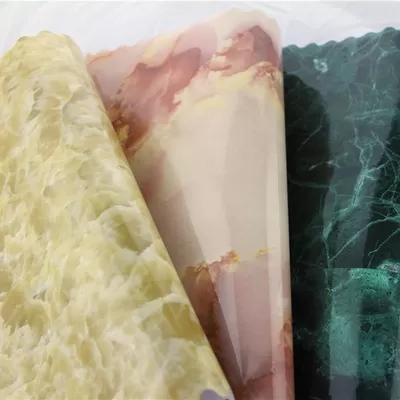

· Transparency

· Adhesion

· Hardness

· Alcohol resistance

· Water resistance

Technical features

Molecular weight, molecular structure of uniform;

Manufacturing air dry priming coat in combination with nitrocellulose ,film features: fast dry,good fullness and flexibility results on metal substrate;

Manufacturing air dry paint in combination with amino resin,film features: fast dry,good fullness and flexibility,weather resistance, good solvent cleaning performance .good compatibility with NC.

Solvent composition

Toluene

References

Formula for Fire Retardant Coating

normal Fast dry

A901 Acrylic Resin 25% 22%

582 Amino Resin 3% 6%

APP 20% 20%

Pentaerythritol 8% 8%

Melamine 5% 5%

Chlorinated Paraffin CP70 4% 4%

Titanium Pigment 10% 10%

Silica Fume 8% 8%

Zinc Borate 2% 2%

Zinc Oxide 0.5% 0.5%

Solvent oil No.200 11.5% 0%

BAC 3% 14.5%

Construction Suggestions

1. The thickness of the single-layer film is 0.3mm, which should be brushed once a day in winter ,or twice a day in summer; A total of 6-8 layers should be brushed.

2. The surface drying time :0.5 hour

The practical drying time(single layer) : 6-12 hours

3. The construction and maintenance period is usually 30-40 days

Laboratory testing recommendations

1. Please apply the paint brushed to the steel plate for testing

2. Pot time ,hardness and related indicators test are suggested to be testing after the maintenance period

3. The detection of intumescent temperature should high than 300 ℃, please pay attention that normally the flame temperature of a lighter or alcohol lamp is less than 300 ℃

4. Pot time is related to the amount of pentaerythritol in the formula. Generally the more pentaerythritol in the formula the pot time is more slow ,however the pot hardness is much better. Therefore, it is recommended to follow the reference formula.

Project Cases

Thermoplastic Liquid Acrylic Resinfor Ultra Thin Fire Retardant Coatings 0

Storage condition

Please put the product in a cool place, and avoid sunlight and rain. Store in original unopened containers and indoor temperature can not exceed the maximum 35℃.

ELEGANT®A901 is a special acrylic resin for fire retardant coating,it is a new generation of air dry modified acrylic resin, which has good compatibility with Aliphatic Hydrocarbon Solvent. It can effectively improve the indicators of fire retardant coating and provide its effective guarantee, and can also make road marking paint.

Our service

We provide existing product lines as well as custom design capability in meeting the needs of customers

We provide sourcing services for any ancillary products

We provide a high level of customer service and support in conjunction with high quality products at competitive prices

Application

· metal productions

· air dry priming coat

· road marking paint

. fire retardant paint

Markets

· metal productions Industry

. fireproof Industry

. road and concrete construction

General Characteristics

· Appearance (gloss, build)

· Transparency

· Adhesion

· Hardness

· Alcohol resistance

· Water resistance

Technical features

Molecular weight, molecular structure of uniform;

Manufacturing air dry priming coat in combination with nitrocellulose ,film features: fast dry,good fullness and flexibility results on metal substrate;

Manufacturing air dry paint in combination with amino resin,film features: fast dry,good fullness and flexibility,weather resistance, good solvent cleaning performance .good compatibility with NC.

Solvent composition

Toluene

References

Formula for Fire Retardant Coating

normal Fast dry

A901 Acrylic Resin 25% 22%

582 Amino Resin 3% 6%

APP 20% 20%

Pentaerythritol 8% 8%

Melamine 5% 5%

Chlorinated Paraffin CP70 4% 4%

Titanium Pigment 10% 10%

Silica Fume 8% 8%

Zinc Borate 2% 2%

Zinc Oxide 0.5% 0.5%

Solvent oil No.200 11.5% 0%

BAC 3% 14.5%

Construction Suggestions

1. The thickness of the single-layer film is 0.3mm, which should be brushed once a day in winter ,or twice a day in summer; A total of 6-8 layers should be brushed.

2. The surface drying time :0.5 hour

The practical drying time(single layer) : 6-12 hours

3. The construction and maintenance period is usually 30-40 days

Laboratory testing recommendations

1. Please apply the paint brushed to the steel plate for testing

2. Pot time ,hardness and related indicators test are suggested to be testing after the maintenance period

3. The detection of intumescent temperature should high than 300 ℃, please pay attention that normally the flame temperature of a lighter or alcohol lamp is less than 300 ℃

4. Pot time is related to the amount of pentaerythritol in the formula. Generally the more pentaerythritol in the formula the pot time is more slow ,however the pot hardness is much better. Therefore, it is recommended to follow the reference formula.

Project Cases

Thermoplastic Liquid Acrylic Resinfor Ultra Thin Fire Retardant Coatings 0

Storage condition

Please put the product in a cool place, and avoid sunlight and rain. Store in original unopened containers and indoor temperature can not exceed the maximum 35℃.