Hardfacing CTC Cast Tungsten Carbide Powder For Drill Bits And Diamond Tools

PRODUCT DESCRIPTION Cast Tungsten Carbide Powder For Hardfacing,Drill Bits And Diamond Tools (Fuse WC,Cast WC,CTC,Crushed WC) Chemical Compositions Grade W T.C F.C Fe Ti Ni Cr Co V BD20101 Balance 3.8-4.2 ≤0.05 ≤0.5 <0.1 3-5 <0.1 <0.1 <0.1 Hardness HRA Micro-hardness ...

PRODUCT DESCRIPTION

Cast Tungsten Carbide Powder For Hardfacing,Drill Bits And Diamond Tools

(Fuse WC,Cast WC,CTC,Crushed WC)

Chemical Compositions

Grade W T.C F.C Fe Ti Ni Cr Co V

BD20101 Balance 3.8-4.2 ≤0.05 ≤0.5 <0.1 3-5 <0.1 <0.1 <0.1

Hardness HRA Micro-hardness HV 0.1 Density g/cm3 Melt Point ℃

93.0-93.7 1700-2500 16.5 2525

Hardfacing CTC Cast Tungsten Carbide Powder For Drill Bits And Diamond Tools 0

Regular Particle size

Particle Size

20-30mesh 100-140mesh

30-40mesh 100-230mesh

40-60mesh 120-170mesh

60-80mesh 140-200mesh

80-120mesh 170-3250mesh

60-325mesh 200-325mesh

80-200mesh -325mesh

Cast Tungsten Carbide:

Chemical Formula:WC/W2C

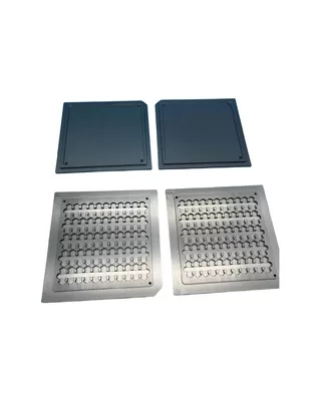

Cast Tungsten Carbide (CTC) is a so-called cast and crushed tungsten carbide.

lt is of irregular particle shape.

Adopted high temperature melting, crushing process.

Due to its high melting point, high hardness, high wear resistance characteristics, make its have the characteristics of high temperature resistance, abrasion resistance, impact resistant.

Products are widely used in mining, oil, metallurgical industry, steel, construction machinery and other industries.

Such as: PDC bit, petroleum drill pipe, TC bearing, etc.

Blends of CTC with alloy powders based on Ni, Fe or Co are used to produce

superior wear protectioning coatings by PTA welding, lasercladding or other wear protective welding applications.

Examples are conveyor screws, fan blades, wear plates. excavator bucket teeth and crusher iaws.

Furthermore. CTC can be used for the production of drill bits.

Related Products:

Cast WC/NiCrBSi alloy powder usd for PTA.

Cast WC/Ni Powder as Matrix Powder used for Oil and Gas equipment.

Cast WC Tube welding rods for surfacing repaired

Hard facing materials series:

Product Boda Code Regular Particle Size Main Performance Spray Process Applicaitons

Cast Tungsten Carbide CTC/Cast WC 60-80Mesh high hardness and high wear resistance. Laser cladding,Arc Welding,PTA,Spray and fuse powder welding PDC bit, oil drill pipe, TC bearing, etc

80-100mesh Tool surface reinforcement

100-140mesh It is especially suitable for surfacing of petroleum and natural gas geological tools

10-2700mesh Metallurgy, construction, grain and oil processing, mining machinery and other industries

200-400mesh

Spherical Cast Tungsten Carbide SCWC/CTC-S 100-200mesh high hardness and high wear resistance. Laser cladding,Arc Welding,PTA,Spray and fuse powder welding PDC bit, oil drill pipe, TC bearing, etc

100-270 Tool surface reinforcement

60-140mesh It is especially suitable for surfacing of petroleum and natural gas geological tools

100-270mesh Metallurgy, construction, grain and oil processing, mining machinery and other industries

Macro Tungsten Carbide Macro WC,MWC 60-80mesh Hard phase blend component for wear resistance Laser cladding,Arc Welding,PTA,Spray and fuse powder welding used as the materials of petroleum

80-200mesh geological drilling tire body

2000-400mesh a new type of cemented carbide material.

-325mesh Mining equipment crushers and milling machinery,Heavy equipment mixer blades,decanters or extruder screws.

Crystalline Tungsten Powder CTP 60-325Mesh strength and wear resistance Vibration and liquid Metal Infitration petroleum drilling diamond bits

100-200mesh as the raw materials of oil perforation pills,high temperature combustion chamber spraying coating

140-325mesh wear resistance and high temperature resistance parts coating for slot or warehouse crashing parts,foklift buckets,crane hopper,screw feeder,ingot tongs and grind device components.

About Boda and advantages.

Hardfacing CTC Cast Tungsten Carbide Powder For Drill Bits And Diamond Tools 1

Hardfacing CTC Cast Tungsten Carbide Powder For Drill Bits And Diamond Tools 2

Hardfacing CTC Cast Tungsten Carbide Powder For Drill Bits And Diamond Tools 3

Hardfacing CTC Cast Tungsten Carbide Powder For Drill Bits And Diamond Tools 4

Hardfacing CTC Cast Tungsten Carbide Powder For Drill Bits And Diamond Tools 5

Cast Tungsten Carbide Powder For Hardfacing,Drill Bits And Diamond Tools

(Fuse WC,Cast WC,CTC,Crushed WC)

Chemical Compositions

Grade W T.C F.C Fe Ti Ni Cr Co V

BD20101 Balance 3.8-4.2 ≤0.05 ≤0.5 <0.1 3-5 <0.1 <0.1 <0.1

Hardness HRA Micro-hardness HV 0.1 Density g/cm3 Melt Point ℃

93.0-93.7 1700-2500 16.5 2525

Hardfacing CTC Cast Tungsten Carbide Powder For Drill Bits And Diamond Tools 0

Regular Particle size

Particle Size

20-30mesh 100-140mesh

30-40mesh 100-230mesh

40-60mesh 120-170mesh

60-80mesh 140-200mesh

80-120mesh 170-3250mesh

60-325mesh 200-325mesh

80-200mesh -325mesh

Cast Tungsten Carbide:

Chemical Formula:WC/W2C

Cast Tungsten Carbide (CTC) is a so-called cast and crushed tungsten carbide.

lt is of irregular particle shape.

Adopted high temperature melting, crushing process.

Due to its high melting point, high hardness, high wear resistance characteristics, make its have the characteristics of high temperature resistance, abrasion resistance, impact resistant.

Products are widely used in mining, oil, metallurgical industry, steel, construction machinery and other industries.

Such as: PDC bit, petroleum drill pipe, TC bearing, etc.

Blends of CTC with alloy powders based on Ni, Fe or Co are used to produce

superior wear protectioning coatings by PTA welding, lasercladding or other wear protective welding applications.

Examples are conveyor screws, fan blades, wear plates. excavator bucket teeth and crusher iaws.

Furthermore. CTC can be used for the production of drill bits.

Related Products:

Cast WC/NiCrBSi alloy powder usd for PTA.

Cast WC/Ni Powder as Matrix Powder used for Oil and Gas equipment.

Cast WC Tube welding rods for surfacing repaired

Hard facing materials series:

Product Boda Code Regular Particle Size Main Performance Spray Process Applicaitons

Cast Tungsten Carbide CTC/Cast WC 60-80Mesh high hardness and high wear resistance. Laser cladding,Arc Welding,PTA,Spray and fuse powder welding PDC bit, oil drill pipe, TC bearing, etc

80-100mesh Tool surface reinforcement

100-140mesh It is especially suitable for surfacing of petroleum and natural gas geological tools

10-2700mesh Metallurgy, construction, grain and oil processing, mining machinery and other industries

200-400mesh

Spherical Cast Tungsten Carbide SCWC/CTC-S 100-200mesh high hardness and high wear resistance. Laser cladding,Arc Welding,PTA,Spray and fuse powder welding PDC bit, oil drill pipe, TC bearing, etc

100-270 Tool surface reinforcement

60-140mesh It is especially suitable for surfacing of petroleum and natural gas geological tools

100-270mesh Metallurgy, construction, grain and oil processing, mining machinery and other industries

Macro Tungsten Carbide Macro WC,MWC 60-80mesh Hard phase blend component for wear resistance Laser cladding,Arc Welding,PTA,Spray and fuse powder welding used as the materials of petroleum

80-200mesh geological drilling tire body

2000-400mesh a new type of cemented carbide material.

-325mesh Mining equipment crushers and milling machinery,Heavy equipment mixer blades,decanters or extruder screws.

Crystalline Tungsten Powder CTP 60-325Mesh strength and wear resistance Vibration and liquid Metal Infitration petroleum drilling diamond bits

100-200mesh as the raw materials of oil perforation pills,high temperature combustion chamber spraying coating

140-325mesh wear resistance and high temperature resistance parts coating for slot or warehouse crashing parts,foklift buckets,crane hopper,screw feeder,ingot tongs and grind device components.

About Boda and advantages.

Hardfacing CTC Cast Tungsten Carbide Powder For Drill Bits And Diamond Tools 1

Hardfacing CTC Cast Tungsten Carbide Powder For Drill Bits And Diamond Tools 2

Hardfacing CTC Cast Tungsten Carbide Powder For Drill Bits And Diamond Tools 3

Hardfacing CTC Cast Tungsten Carbide Powder For Drill Bits And Diamond Tools 4

Hardfacing CTC Cast Tungsten Carbide Powder For Drill Bits And Diamond Tools 5